Bamboo fabric has many names, such as Bamboo rayon, retting, bamboo linen, or bamboo rayon. Its names vary due to its long history of wide application on clothes in many cultures.

These days, with the ever-growing trend of new fabric from bamboo trees, many people have bamboo fabric products in their wardrobes.

Bamboo Fabric: What Is It?

It is a term to describe a variety of textiles manufactured from the bamboo tree. For thousands of years, people have been using bamboo to create fabrics, but the technique of turning this tough and fast-growing hardwood into cloth has only recently become clear.

Bamboo cloth has a complicated history. While certain varieties of this fabric are ecologically friendly and ethically manufactured, others may be detrimental to the environment or the labor who create them. It’s critical to understand more about the textile business around bamboo before choosing the correct sort of bamboo cloth.

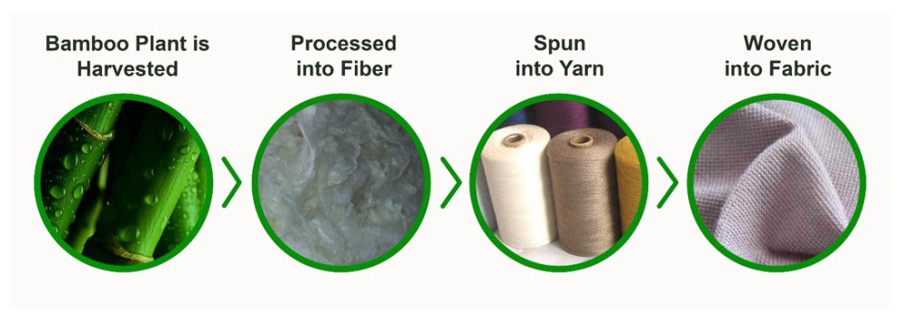

How People Produce Bamboo Fabric?

1. The Viscose Technique

Bamboo textiles can be created in various ways, depending on the sort of cloth of the end product. The bulk of bamboo fabric sold today is bamboo viscose, which is inexpensive to make despite having environmental and labor risks.

The name “viscose” refers to any fabric manufactured using the viscose technique, which showed up in the early twentieth century. This material is one of the most recent forms of rayon, a semi-synthetic textile that imitates the attractive characteristics of silk.

#Step one

The harvesting of cellulose from wood pulp is the first step in the processing of viscose rayon. People break the wood down into tiny bits to extract the cellulose and then sink them into chemical solvents.

There are various methods to make viscose rayon, and virtually all of them contain hazardous chemicals such as caustic soda.

#Step two

Harvested cellulose goes through the compacting process to turn into sheets, which contact carbon disulfide, filtered to create a usable fabric. People then force the cellulose through a spinneret, which separates it into strands.

Now, these strands are in a solution of sulfuric acid to generate filaments, and these filaments then turn into yarn through spinning, making them fabric after weaving.

2. The Closed-loop Production Technique

A closed-loop production technique may be available to produce bamboo cellulose. Closed-loop rayon manufacturing, unlike viscose rayon creation, does not chemically change the composition of the cellulose utilized, resulting in a textile that may be entirely natural.

Although the solvent needed to manufacture conventional viscose rayon typically disappears and finishes in the biosphere, the solvents used during closed-loop rayon manufacturing may be reused several times, substantially reducing the industry’s environmental effect.

3. The Natural Enzyme Technique

The bamboo fabric is of the finest grade using non-cellulose extraction methods. Rather, chopped bamboo hardwood fibers go through a process in which people use a natural enzyme to treat the wood.

Then, the worker washes bamboo fibers and spins them into yarn. The fabric produced by this technique is frequently referred to as bamboo linen since the yarn has a smooth feel. This process of producing bamboo fabric is not environmentally damaging, and the final cloth is robust and long-lasting.

Most varieties of bamboo fabric, on the other hand, are not created using this mechanical method. To guarantee that you’re obtaining high-quality bamboo fibers, be sure to use a mechanical method instead of a chemical approach.

In Which Areas Does Bamboo Fabric Apply?

In essence, this sort of cloth applies to almost every situation that uses cotton. Some customers may even prefer this fabric to cotton because of its numerous advantages.

Bamboo cloth, for example, is very absorbent and stretchier than cotton. It’s simple to weave this cloth into high-thread-count textiles, which are frequently thinner and more beautiful.

#Household Textiles

The bamboo fabric appears in sheets, towels, blankets, hand towels, and other household textiles. Owing to its softness and resilience, people use it to produce clothes. In addition, bamboo fabric can turn into underwear, T-shirts, socks, and other clothing that directly touches the skin.

#Intimate Apparel

Because of its supposed antimicrobial properties, some companies tend to use this kind of cloth for intimate apparel.

Yet, studies have shown that antibacterial qualities associated with bamboo are mostly available in the original product. After this kind of wood has already been turned into clothes, these antimicrobial effects are mostly absent.

It’s crucial to note that only bamboo cloth produced through mechanical methods has the positive qualities that make it so popular with customers. Bamboo rayon and related semi-synthetic textiles are not as smooth or elastic as genuine rayon, and their antibacterial properties are minimal.

Where Is Bamboo Fabric Made?

Bamboo cloth has been existing for centuries and centuries in East Asia. For example, civilizations in India and China have made this cloth for countless centuries and still hold bamboo fabric festivals each year. Bamboo manufacturing has traveled across the world due to the greater sustainable development of this form of wood.

Because it can grow in various conditions, this wood species is becoming increasingly popular in Western countries like the US and Europe. As a result, nearly every developing or developed nation worldwide supplies and exports some kind of bamboo fabric.

China, on the other hand, is the world’s greatest source of this sort of plant. This economic reality is unsurprising; bamboo has long been a popular material for manufacturing textiles in China.

However, there seems to be a nasty side behind why bamboo cloth manufacture is so prominent in China. Due to high competition against multinational textile firms favored by the government, local firms had to relocate and try their best to reduce manufacturing costs to compete.

As Chinese manufacturers do not get the incentives to grow their goods in a good or sustainable way, the creation of bamboo fabric in China is more ecologically harmful than usual since producers try to apply inexpensive methods to produce bamboo fabric as cheaply as possible.

Pakistan, India, and Indonesia are other important suppliers of this cloth. While a huge proportion of this sort of fabric is made in The US, most of it is for internal use, not adding to the nation’s exports.

What Is The Cost of Bamboo Fabric?

Cotton is typically cheaper than viscose or other semi-synthetic textiles manufactured from bamboo wood. Customers with a tight budget can buy cotton as an alternative instead of buying products from bamboo wood.

On the other hand, authentic bamboo fabric is often more pricey than cotton- often ranging from 20 USD to over 50 USD/ product. However, It might be less costly than premium cotton such as Pima cotton, Egyptian cotton, and Supima cotton.

How Many Types Of Bamboo Fabric Are There?

I can name three main kinds of bamboo fabric, including:

Bamboo Viscose

This sort of bamboo fabric is quite similar to other viscose fabrics. People choose bamboo over other sorts of hardwood because this fabric saves production costs money on production. However, its viscose format is not an advantage, and customers should avoid confusing this kind of fabric with real mechanically-made bamboo fabric.

Lyocell-type Bamboo Fabric

This fabric is comparable to viscose, except it is manufactured using a closed-loop manufacturing process. The chemical composition of the cellulose utilized to manufacture this kind of fabric is not different throughout the manufacturing process, ensuring that it keeps many of the positive properties seen in conventionally made bamboo fabric.

Mechanically Make Authentic Bamboo Fiber

Only this sort of cloth deserves the title of “real bamboo fabric.” It is more time-consuming and costly to manufacture, but it provides considerably more advantages than textiles not created mechanically. This bamboo cloth is extremely robust, long-lasting, and smooth.

What Is The Environmental Impact of Bamboo Fabric?

People often see bamboo fabrics as environmentally friendly cloth, and in some aspects, this is true. Bamboo, for example, is very easy to cultivate, develops fast, and grows in locations where other crops cannot.

As a result, in principle, bamboo cultivation has a low impact on the environment. It is also up to individual bamboo growers to guarantee that their crops have a minimal environmental impact.

1. Deforestation

Unfortunately, the current demand for bamboo has driven several Chinese companies to clear forests of other species to cultivate bamboo, thereby negating the crop’s environmental advantages. The Chinese Communist Party had to enact laws forbidding this conduct in the late 1990s.

2. Harmful Chemicals

Even while modern bamboo growing is generally low-impact on the environment, the method of making bamboo viscose is far from it. While customers are unlikely to be exposed to harmful chemicals when wearing or using bamboo fabric, some hazardous chemicals convert raw bamboo into cellulose to create rayon.

The lye needed to convert bamboo wood into a cellulose-extracting material, for example, is seldom reused. Furthermore, carbon disulfide is an essential component of the rayon manufacturing process, and it is difficult to recover this hazardous chemical after utilizing it.

Bamboo manufacturing in developing countries like China has provoked controversy. Most Chinese bamboo textile companies, for example, put their employees to the gaseous carbon disulfide produced during the bamboo rayon manufacturing process.

3. Unsafe Working Environment

The method of making viscose rayon is time-consuming and wasteful. Any fabric created with tree cellulose generates a lot of trash, but you can reduce this wastage sustainably with the appropriate production techniques.

However, the waste generated by the manufacture of viscose rayon is polluted with carbon disulfide, a hazardous substance that can cause problematic health issues.

Carbon disulfide is neurotoxic and may potentially harm organs. Workers contracted to this substance are at risk of developing psychosis, liver problems, coma, and poor eyesight, as well as heart problems.

Although some firms can safeguard their employees against carbon disulfide, the Chinese government’s authorized limits for this chemical are considerably over the safety threshold stated by experts.

4. On The Bright Side

Bamboo cellulose is suitable for closed-loop manufacturing processes, unlike cellulose from other plants frequently utilized for viscose rayon manufacture.

As a result, bamboo may make textiles comparable to lyocell, yet the lyocell manufacturing method produces no hazardous waste. Nevertheless, the large proportion of bamboo fabric is rayon, which comes through environmentally damaging techniques.

It is crucial to note that the making of real bamboo fiber is environmentally friendly. Avoid bamboo viscose and go for real fibers or lyocell-like bamboo cellular textiles if you want to enjoy the benefits promised by bamboo textile producers.

What Are The Benefits of Bamboo fabric?

You may want to know about the benefits of bamboo textile; here they are.

Firstly, bamboo fabric safeguards you from skin cancer by using natural UV protection. Natural bamboo fibers are non – toxic, meaning it does not induce allergic responses.

In addition, wearing bamboo clothes means that you are helping preserve the environment by wearing the world’s most eco-friendly fabric.

Another feature of bamboo fabric is antimicrobial, which prevents odors and makes you feel and smell great.

In the summertime, due to its strong perspiration absorbent (wicks moisture away from the skin for evaporation), bamboo fabric outfit can make you drier, while it can keep the warmth during the winter.

You’ll adore the way it feels because it’s one of the softest textiles in the world.

Conclusion

Hopefully, this article has shown you everything you need to know about bamboo fabric.

As you know the environmental benefits and other advantages of bamboo fabric clothes, what are your thoughts on this interesting material?

https://sewport.com/fabrics-directory/bamboo-fabric

Material Guide: Is Bamboo Fabric a More Sustainable Option for Fashion?

https://www.fibre2fashion.com/industry-article/3842/benefits-of-bamboo-fabric

Help Us! Share on: